In the realm of civil engineering and construction, the stability and strength of soil is paramount. Throughout the years, innovative materials have emerged that aid in enhancing soil characteristics. Among these materials, uniaxial geogrids have garnered attention for their significant role in soil reinforcement. As a key element of modern geotechnical engineering, the use of uniaxial geogrids has become widespread in various applications, from road construction to retaining wall systems. However, to maximize their effectiveness, implementing field monitoring is essential.

Understanding Uniaxial Geogrids

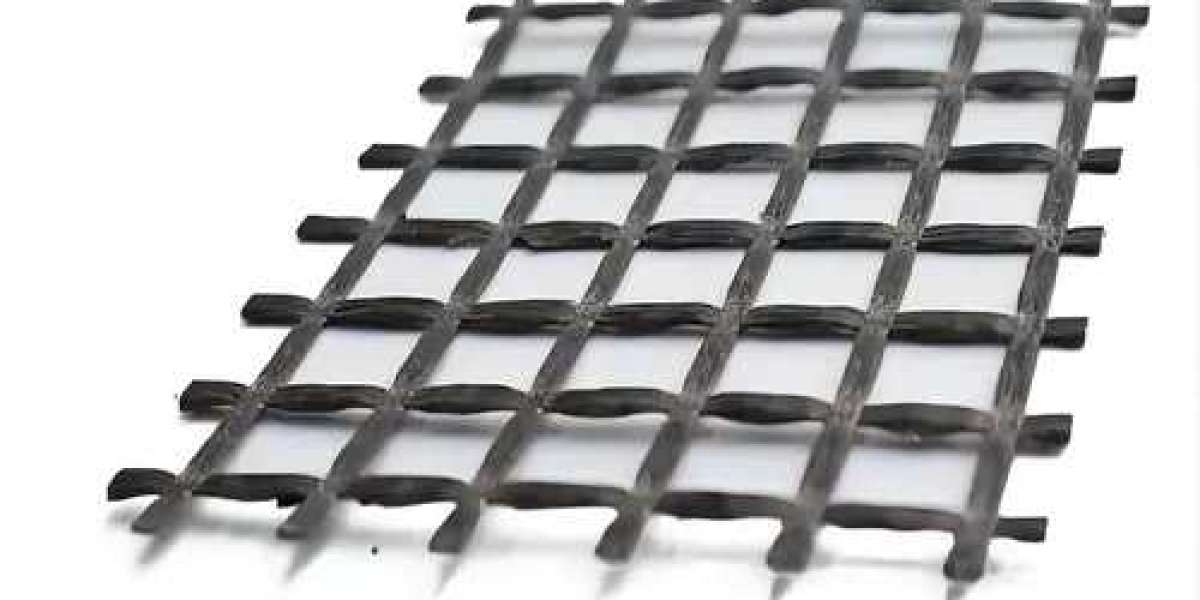

Uniaxial geogrids are geosynthetic materials made from polymers, typically high-density polyethylene (HDPE) or polypropylene. They are designed to provide soil reinforcement in applications where soil stability is a concern. The primary function of uniaxial geogrids is to distribute loads over a larger area, reducing localized stress on soil and improving its bearing capacity. Consequently, they are often utilized in construction projects involving embankments, roadways, and railway applications.

As the demand for uniaxial geogrids continues to rise, various manufacturers and suppliers have emerged in the market. Notably, Uniaxial geogrid manufacturer develop the geogrids to meet specific engineering requirements, while uniaxial geogrid suppliers provide these essential materials to construction sites in diverse regions, including uniaxial geogrid in India.

The Need for Field Monitoring

Field monitoring involves the collection of real-time data on the performance of geogrid installations and the surrounding environment. It entails various measurement techniques and technological tools to observe the behavior of soil and structures under different conditions. For uniaxial geogrid projects, field monitoring is crucial for the following reasons:

1. Ensuring Structural Performance

One of the primary benefits of field monitoring is the assurance of structural performance. By monitoring how uniaxial geogrids interact with soil, engineers can assess whether the geogrids are performing as intended. This involves measuring parameters such as displacements, stresses, and strains in real-time. Early detection of issues allows engineers to take corrective actions before they escalate into significant problems, ultimately extending the life of the project.

2. Enhancing Design Accuracy

Field monitoring provides valuable data that can enhance the accuracy of future project designs. Understanding how uniaxial geogrids respond under varying conditions can inform engineers and geotechnical professionals about the best design practices for upcoming projects. This continuous feedback loop fosters a culture of learning and innovation within civil engineering, allowing for the implementation of improved designs that account for real-world scenarios.

3. Optimizing Material Usage

Accurate field monitoring allows for better optimization of materials used in a project. By analyzing the performance of uniaxial geogrids, engineers can determine if the quantity and type of geogrids used are adequate or if modifications are needed. This not only reduces material waste but can also lead to significant cost savings for construction companies. Furthermore, when working with reputable uniaxial geogrid manufacturers, the material selection can be fine-tuned based on real-time feedback.

4. Supporting Regulatory Compliance

In many regions, including India, there are strict regulations governing construction practices and materials used in infrastructure projects. Field monitoring helps ensure that uniaxial geogrid projects comply with these regulatory standards. By providing verifiable data on geogrid performance and the overall structural integrity, field monitoring results can be presented to regulatory bodies to demonstrate compliance and secure necessary approvals.

5. Mitigating Risks and Enhancing Safety

Every construction project comes with inherent risks. Field monitoring is a proactive approach to risk management, particularly in projects involving uniaxial geogrids. By consistently tracking how the Uniaxial geogrid in India interacts with surrounding soil and other materials, potential issues such as soil erosion, settlement, or lateral movement can be identified early on. This mitigates the risk of structural failures, which can endanger the project and the safety of workers and users.

6. Providing Long-term Monitoring Solutions

Field monitoring is not limited to the immediate construction phase; it can also extend into the operational phase of a project. Long-term monitoring systems help track the ongoing performance of uniaxial geogrids as environmental conditions change over time. These systems offer insights into how the geogrids continue to perform and whether any maintenance or adjustments are necessary. Such longevity enhances the sustainability of construction projects, resonating particularly in environmentally conscious markets like India.

7. Leveraging Technological Advancements

The rise of innovative technologies has revolutionized field monitoring. Tools such as geotechnical sensors, satellite imaging, and remote sensing technologies play a critical role in gathering data and visualizing changes in real-time. These technologies provide engineers with precise measurements that traditional methods cannot achieve. This technological edge facilitates better decision-making during construction and afterward.

Conclusion

Field monitoring presents numerous benefits for uniaxial geogrid projects that cannot be understated. From ensuring structural performance to optimizing resource use and enhancing safety, the data collected through monitoring practices shapes the future of infrastructure development. As the construction industry in India continues to expand, moving towards more advanced materials and techniques, the role of uniaxial geogrids and field monitoring will undoubtedly evolve.

As companies engage with uniaxial geogrid manufacturers and Uniaxial Geogrid Suppliers, it is crucial to implement robust monitoring systems that not only provide immediate insights but also contribute to the long-term sustainability and efficacy of projects. By embracing field monitoring, stakeholders create a foundation where innovation leads to safer, reliable, and more efficient engineering solutions that stand the test of time.

Frequently Asked Questions (FAQs)

What is a uniaxial geogrid and how does it work?

A uniaxial geogrid is a polymer-based mesh structure that provides soil reinforcement through tensioning and interlocking with the soil. It helps evenly distribute loads, enhancing stability and reducing deformation.

Where are uniaxial geogrids typically used?

Uniaxial geogrids are commonly used in applications such as road construction, embankments, retaining walls, and slope stabilization projects.

Why is field monitoring important in geogrid projects?

Field monitoring is essential because it allows for the early detection of potential failures, validates design assumptions, enhances project management, and supports compliance with safety regulations.