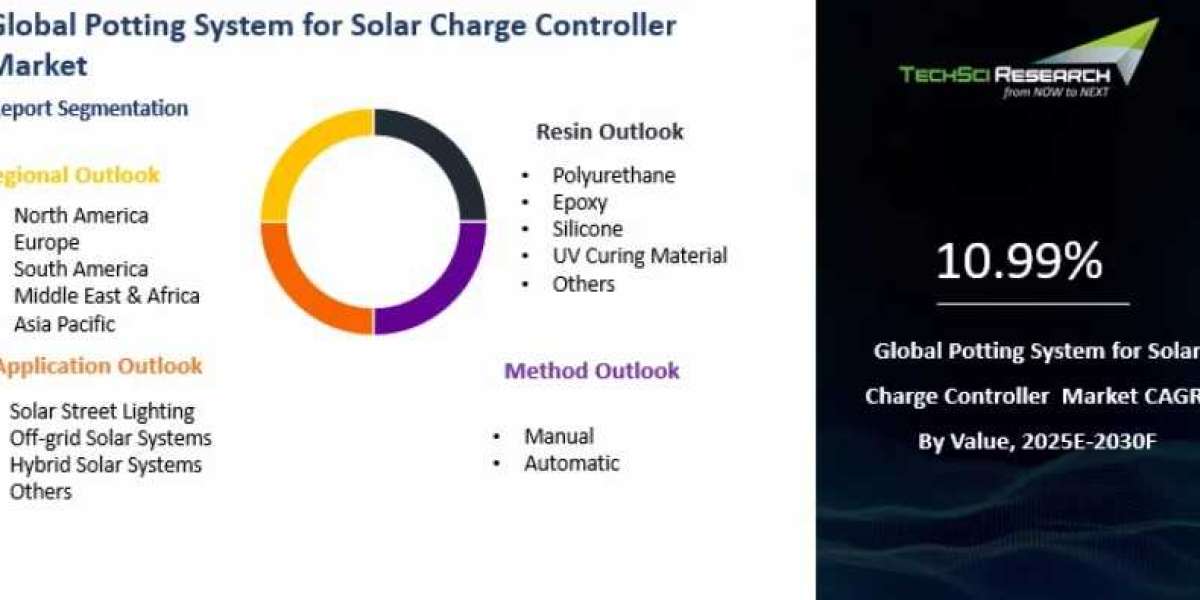

According to a recent TechSci Research report, “Potting System for Solar Charge Controller Market – Global Industry Size, Share, Trends, Competition Forecast Opportunities, 2020–2030F”, the Global Potting System for Solar Charge Controller Market was valued at USD 2.54 billion in 2024 and is projected to reach USD 4.79 billion by 2030, growing at a CAGR of 10.99% during the forecast period.

The market is undergoing a significant transformation, shaped by trends in sustainability, automation, material innovations, and regional growth opportunities. Manufacturers are increasingly focusing on eco-friendly compounds, automated potting systems, and advanced resins to ensure durability and reliability of solar charge controllers across diverse environments.

Sustainability Driving Market Transformation

One of the most important market shifts is the adoption of eco-friendly potting materials. With rising concerns about environmental impact, manufacturers are investing in low-VOC, halogen-free, and biodegradable formulations. Eco-friendly compounds have gained substantial traction, representing nearly 30% of new product launches in recent years.

In Europe, regulations such as REACH and RoHS have accelerated the replacement of conventional epoxies with sustainable alternatives. Customer demand also reflects this trend—surveys suggest that over 60% of solar developers now prefer suppliers with green-certified offerings.

This movement aligns with the broader renewable energy sustainability push, where not only energy generation but also component manufacturing is expected to follow eco-friendly practices. With the global expansion of green building standards and ESG-focused investments, the demand for sustainable potting solutions is set to accelerate, positioning eco-friendly resins as a key differentiator for manufacturers in competitive markets.

Automation Enhancing Efficiency and Reliability

Automation is reshaping the production landscape for solar charge controllers. Traditionally reliant on manual processes, the industry is transitioning rapidly to automated atmospheric and vacuum potting systems.

Currently, automated systems account for nearly 70% of large-scale manufacturing. The shift is driven by:

Precision and defect reduction – Automated potting ensures consistent application and minimizes errors.

Vacuum potting advantages – This technique reduces air voids by over 90%, significantly improving insulation and thermal conductivity.

Improved throughput – Automated dispensing has boosted production efficiency by 30–40%, helping manufacturers meet growing demand.

With rising labor costs and the need for higher scalability, automation is expected to become the industry standard. The integration of robotics, AI-based monitoring, and real-time process control will further improve accuracy, reliability, and cost efficiency in the years ahead.

Market Segmentation by Resin: Epoxy Leading Growth

Epoxy Resins: The Fastest-Growing Segment

Based on resin type, epoxy is emerging as the fastest-growing segment in the global market. Its popularity is attributed to its:

Superior mechanical strength – Ensuring long-term durability.

Resistance to harsh environments – Protecting electronics from temperature fluctuations, moisture, and chemicals.

High dielectric properties – Preventing short circuits and ensuring safe operation.

Epoxy resins are particularly suitable for utility-scale and commercial solar projects, where reliability is critical. Unlike polyurethane, which offers flexibility, epoxy delivers structural rigidity—ideal for high-performance applications.

Applications in Harsh Conditions

The demand for epoxy is further strengthened by the expansion of solar projects in challenging terrains such as Middle Eastern deserts and off-grid rural regions in Asia and Africa. These environments require potting materials that ensure durability under extreme weather conditions.

Advancements in Epoxy Technology

Recent innovations such as low-viscosity epoxy formulations have enhanced ease of application, ensuring better penetration into complex assemblies while reducing process times. Additionally, epoxy’s thermal management properties make it the preferred choice for high-efficiency charge controllers, which demand effective heat dissipation.

With applications expanding across defense, industrial, and commercial solar installations, epoxy’s role as the fastest-growing resin category is expected to strengthen significantly during the forecast period.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the " Global Potting System for Solar Charge Controller Market"

https://www.techsciresearch.com/report/potting-system-for-solar-charge-controller-market/30620.html

Regional Outlook: Asia Pacific Leading Growth

Among all regions, Asia Pacific is the fastest-growing market for potting systems in solar charge controllers. Several factors contribute to this strong growth trajectory:

Rapid Solar Expansion – Countries like China, India, Japan, and Australia are leading solar PV adoption, creating substantial demand for advanced charge controllers.

Diverse Climatic Conditions – From humid Southeast Asia to arid regions in India and western China, extreme weather drives the need for reliable potting solutions that protect against environmental stress.

Off-Grid and Rural Deployments – Growing demand for microgrids and off-grid solar systems in rural Asia increases reliance on durable potting systems for affordable controllers.

Strong Manufacturing Base – Asia Pacific, led by China, is also a hub for electronics and potting material production, ensuring cost competitiveness and availability.

Government and Policy Support

Policies like India’s National Solar Mission and China’s 2030 carbon neutrality goals further fuel solar adoption. These initiatives indirectly create significant opportunities for potting system providers.

Investment and Expansion

Rising foreign direct investments in solar projects across countries such as Vietnam, Indonesia, and the Philippines add to the growth momentum. Combined with favorable policy frameworks, Asia Pacific is expected to remain the fastest-growing regional market through 2030.

Competitive Landscape and Industry Outlook

The competitive landscape of the global potting system market is shaped by innovation in eco-friendly materials, automation technologies, and regional manufacturing capabilities. Companies investing in sustainable product portfolios and advanced automation systems are likely to secure long-term growth.

As demand for solar charge controllers rises in both developed and emerging economies, suppliers must focus on:

Offering green-certified potting materials to meet regulatory and customer expectations.

Enhancing automation and process monitoring for large-scale efficiency.

Targeting emerging markets in Asia and Africa where solar adoption is accelerating.

Conclusion

The Global Potting System for Solar Charge Controller Market is set for robust growth, nearly doubling in size from USD 2.54 billion in 2024 to USD 4.79 billion by 2030. Sustainability and automation stand out as the two most powerful forces driving industry transformation, while epoxy resins and Asia Pacific emerge as the fastest-growing segments.

With renewable energy adoption accelerating worldwide, potting systems are becoming a critical enabler of durability, reliability, and efficiency in solar charge controllers. Manufacturers that align with eco-friendly practices, embrace automation, and expand into high-growth regions are expected to lead the market in the years ahead.

Key market players in the Global Potting System for Solar Charge Controller market are:

Henkel

Dow

3M Company

Wacker Chemie

Momentive Performance Materials

Master Bond

ELANTAS PDG Inc

Hexion

Alchemie Ltd

Elchem Silicones

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=30620

Customers can also request for 10% free customization on this report.

“The global potting system for solar charge controller market presents significant opportunities driven by the rapid expansion of solar power adoption worldwide. Emerging markets in Africa, Latin America, and Southeast Asia are investing heavily in off-grid and rural electrification, creating demand for reliable, durable controllers with advanced potting protection. Technological advancements, such as eco-friendly resins and automated potting equipment, provide opportunities for innovation and differentiation. Strategic partnerships between material suppliers and solar manufacturers can enhance supply chain resilience.

Additionally, increasing emphasis on sustainability and recyclability of potting compounds opens a pathway for green solutions, positioning firms ahead in the renewable energy transition.” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based Global management consulting firm.

“Potting System for Solar Charge Controller Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Resin (Polyurethane, Epoxy, Silicone, UV Curing Material, Others), By Method (Manual, Automatic), By Application (Solar Street Lighting, Off-grid Solar Systems, Hybrid Solar Systems, Others), By Region, and By Competition, 2020-2030F,” has evaluated the future growth potential of Global Potting System for Solar Charge Controller Market and provides statistics information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Potting System for Solar Charge Controller Market.

Contact

TechSci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

M: +13322586602

Email: [email protected]

Website: https://www.techsciresearch.com