The die casting process has come a long way from its traditional roots, evolving through technological innovation to meet the ever-increasing demands of modern manufacturing. With the introduction of real-time process monitoring and AI-driven quality control systems, manufacturers can now achieve tighter tolerances and reduce defects significantly. Sensors embedded within machines allow for constant feedback loops, ensuring that temperature, pressure, and material flow are precisely controlled throughout the cycle. This level of precision was previously unthinkable, but it has now become a standard in high-volume production environments.

Another critical advancement is the integration of simulation software into the die casting process. These programs enable engineers to model the entire casting procedure before production begins, reducing the need for trial-and-error methods and minimizing waste. Furthermore, simulation tools help optimize mold designs, predict potential defects, and reduce lead times. These technological improvements not only boost efficiency but also make the die casting process more cost-effective and environmentally friendly by reducing scrap and energy consumption.

Automation and Robotics in Die Casting

Automation has become an indispensable component of the modern die casting process. Robotic arms are now commonly used for tasks such as spraying lubricants, removing castings from molds, and performing secondary operations like trimming or deburring. These robots work faster and more consistently than human operators, significantly increasing productivity while ensuring higher-quality output. In hazardous environments with high temperatures and molten metals, automation also enhances worker safety by minimizing direct human exposure.

The introduction of collaborative robots, or "cobots," marks a new phase in automation. Unlike traditional industrial robots, cobots are designed to work alongside humans, providing flexibility and adaptability in the production line. They can be easily reprogrammed for different tasks, making them ideal for short-run production or rapidly changing product designs. As artificial intelligence continues to evolve, these robotic systems will become smarter and more autonomous, further transforming the die casting process into a highly efficient and flexible manufacturing solution.

Material Innovations and Sustainability

The die casting process is being revolutionized by the development of new alloys and materials that are lighter, stronger, and more environmentally friendly. Traditional materials such as aluminum, magnesium, and zinc are being enhanced through alloying and new fabrication techniques to meet the requirements of modern industries, particularly automotive and aerospace. These advanced materials offer better thermal and mechanical properties, enabling the production of more durable and efficient components with thinner walls and more complex geometries.

Sustainability is becoming a central concern in the die casting process. Manufacturers are investing in closed-loop recycling systems to recover and reuse scrap metal, drastically reducing raw material consumption. Water and energy usage are also being optimized through innovations in cooling and heating systems. Additionally, the use of biodegradable lubricants and release agents is gaining popularity as companies strive to reduce their environmental footprint. As the industry continues to embrace green practices, the die casting process is poised to become a key player in the global movement toward sustainable manufacturing.

Integration with Industry 4.0 and Smart Manufacturing

The rise of Industry 4.0 is having a profound impact on the die casting process. By incorporating IoT (Internet of Things) devices, data analytics, and cloud computing, manufacturers can gain unprecedented insight into every aspect of production. Machines can now communicate with each other and share performance data in real time, enabling predictive maintenance and minimizing downtime. This interconnectedness leads to a smarter, more responsive manufacturing environment where decisions can be made based on real-time information rather than historical data.

Digital twins are also emerging as a powerful tool in die casting. These virtual replicas of physical systems allow engineers to simulate and optimize the die casting process before making changes to the actual production line. By comparing the digital twin to real-time data from the factory floor, operators can identify inefficiencies and make adjustments without disrupting operations. This level of digital integration is transforming the die casting process from a rigid, linear system into a dynamic, data-driven model that can adapt to changing market demands and operational challenges.

Expanding Applications and Global Market Growth

The die casting process is no longer confined to traditional industries like automotive and consumer electronics; it is now finding applications in renewable energy, medical devices, and even aerospace and defense. Components that require high strength-to-weight ratios, complex geometries, and excellent dimensional accuracy are ideal candidates for die casting. As new technologies emerge, the demand for die-cast parts is expected to grow exponentially, opening up new opportunities for manufacturers across the globe.

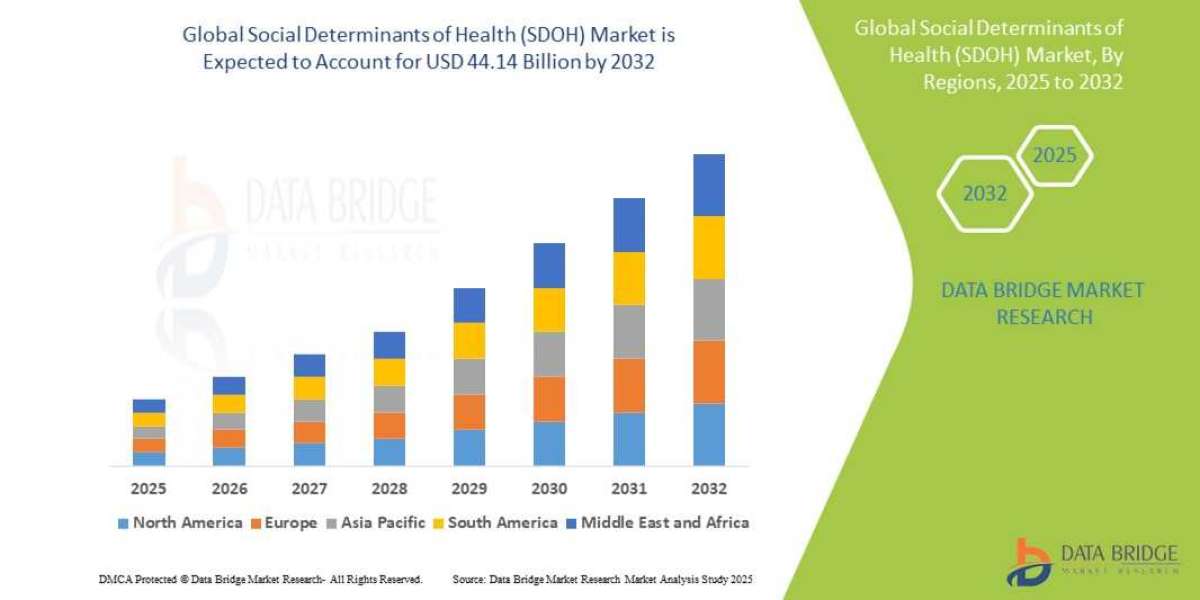

Global market trends indicate a promising future for the die casting industry. According to recent market analyses, the die casting market is projected to grow steadily over the next decade, driven by increased demand for lightweight components and energy-efficient manufacturing processes. Countries such as China, India, and Mexico are becoming major hubs for die casting, thanks to lower labor costs and favorable manufacturing environments. However, to stay competitive, manufacturers worldwide must continue investing in research, innovation, and workforce development to meet the evolving needs of this rapidly expanding market.

Conclusion

The die casting process is undergoing a significant transformation, fueled by technological innovation, automation, sustainable practices, and the advent of smart manufacturing. With continued investment in research and development, the industry is poised to tackle new challenges and seize emerging opportunities across various sectors. As more manufacturers embrace the future of the die casting process, we can expect to see a more efficient, adaptable, and environmentally responsible approach to industrial manufacturing.