As global regulations and consumer preferences pivot toward sustainability, Kraft Take Out Box Manufacturers are redefining food packaging by merging ecological responsibility with commercial viability. These innovators are transforming humble kraft materials into high-performance solutions that meet both regulatory mandates and brand-driven environmental goals, positioning kraft boxes as the cornerstone of the zero-waste movement.

The shift begins with material reinvention. Leading manufacturers now integrate agricultural byproducts like sugarcane bagasse and rice husk ash into kraft pulp, enhancing structural durability while reducing reliance on virgin wood fibers. Advanced extrusion technologies enable water-resistant coatings derived from plant-based waxes, eliminating the need for synthetic chemicals and aligning with certifications like OK Compost and FSC. This ensures boxes withstand hot soups and oily foods without compromising biodegradability—a critical advantage as cities like Paris and Seoul enforce strict single-use plastic bans.

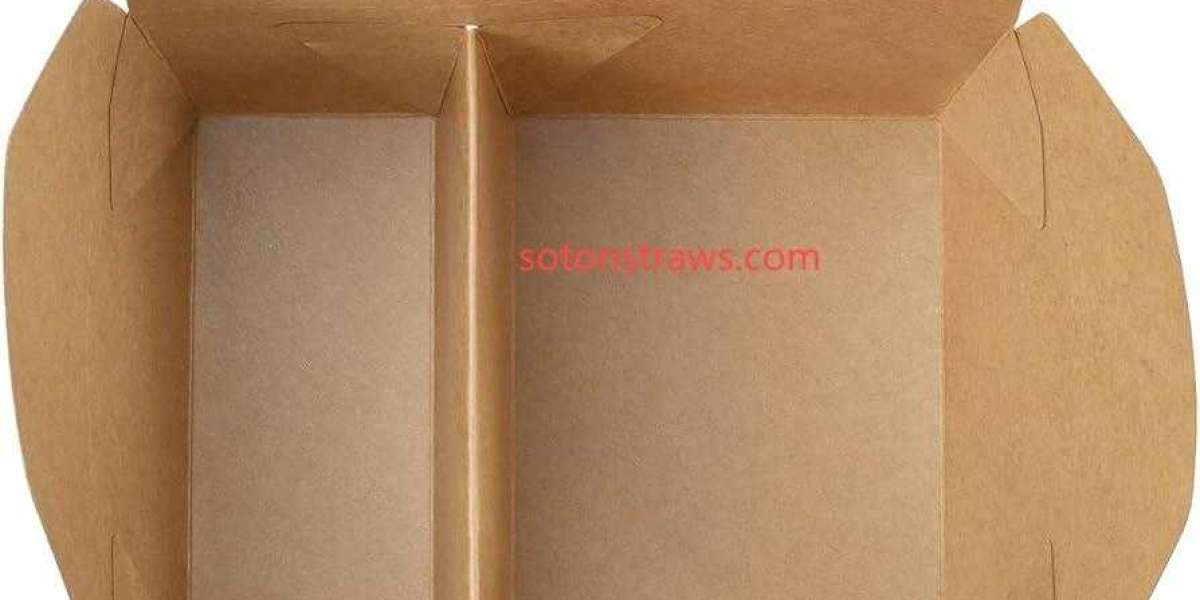

Customization drives market differentiation. Kraft Take Out Box Manufacturers offer tailored printing services, embedding brand logos with soy-based inks or Relief embossing process for luxury aesthetics. Modular designs cater to diverse culinary needs—foldable burger boxes with vented lids prevent sogginess, while compartmentalized trays suit multi-course meals. Such versatility appeals to fast-casual chains and upscale restaurants alike, enabling brands to showcase sustainability as a core identity rather than a compliance checkbox.

Supply chain transparency is equally pivotal. Blockchain-enabled traceability systems allow consumers to scan QR codes and track a box’s journey from responsibly managed forests to compost bins. This builds trust in an era of greenwashing skepticism while meeting EU directives like the Circular Economy Action Plan. Partnerships with coastal communities for reed harvesting further embed social responsibility, linking eco-packaging to ecosystem restoration and rural economic empowerment.

The rise of “zero-waste takeout” programs amplifies kraft’s relevance. Inspired by Denmark’s reusable cup initiatives, manufacturers now pilot deposit schemes where customers return used boxes for sanitization and reuse. This circular model not only slashes packaging costs for businesses but also fosters consumer loyalty through participatory sustainability.

Looking ahead, AI-driven lifecycle assessments and smart manufacturing will optimize material efficiency, while edible coatings derived from seaweed could redefine end-of-use scenarios. As carbon tariffs reshape global trade, kraft’s low-carbon footprint positions it as a strategic asset for brands navigating green transitions.

click sotonstraws.com to reading more information